An Aussie icon is what Shawn’s Datsun 1200 Coupe could be described as these days…

After we completed a few bolt on mods and an ECU upgrade to his cousins’ VL commodore, Shawn liked what he saw. He soon dropped into PZP to have a chat to Chris about shaking up his own B110 Datto. The Sunny was reasonably modified; with a mild built 1.8L turbocharged CA18DET power plant already in place, S13 running gear and a built 4 speed shift-kitted auto with high stall converter made it get up a boogie, even with the stock turbo running a few extra pounds of boost.

The aim of this build was to attempt to give Shawn a few more heart palpitations every time he mashed the throttle wide open: we were to addon to what was already in place, without blowing the budget out of the water.

A decision was made to upgrade the intake and exhaust manifolds to accommodate a new Garrett G30-660 turbocharger. We’d keep the existing motor untouched for now and clean up the engine bay as well as chop out some unnecessary wiring and retain the old, but still suitable, Motec M48 ECU.

Our usual go-to components were on the order straight away, these included:

– Garrett G30-660 turbocharger

– 6boost exhaust manifold

– Turbosmart Gen V 45mm wastegate

– Plazmaman billet intake manifold with matching throttle body and fuel rail

– Raceworks performance fittings and hoses

Once our parts arrived, after some COVID delays and the normal lead times on made-to-order CA18 parts, we got straight into it. Shawn opted to get some maintenance items completed at the same time, these included a new timing kit, renewing the crank and camshaft oil seals and a new water pump was installed while the front end was stripped down.

As you can see, the engine bay looked a little dated when we started…. The hot and cold side of the engine was removed, some coolant and oil hoses were refreshed whilst they were accessible with the manifolds off. Some external modifications to the oiling system were made along with modifications to the lower intake manifold runners. Although the cylinder head ports are tiny and we’d love to have pulled the head for some work and some bigger camshafts, it was out of scope and leaves Shawn with something to ponder for his next round of mods.

The rocker covers and timing covers were given a fresh coat of VHT wrinkle black paint for a more modern look and our attention was then turned to bolting on the good stuff! High mounting the turbo in the engine bay was an absolute given… why spend good money on these things if you can’t show them off right!?! From there our Plazmaman parts bolted up perfectly as usual and fabrication was then underway.

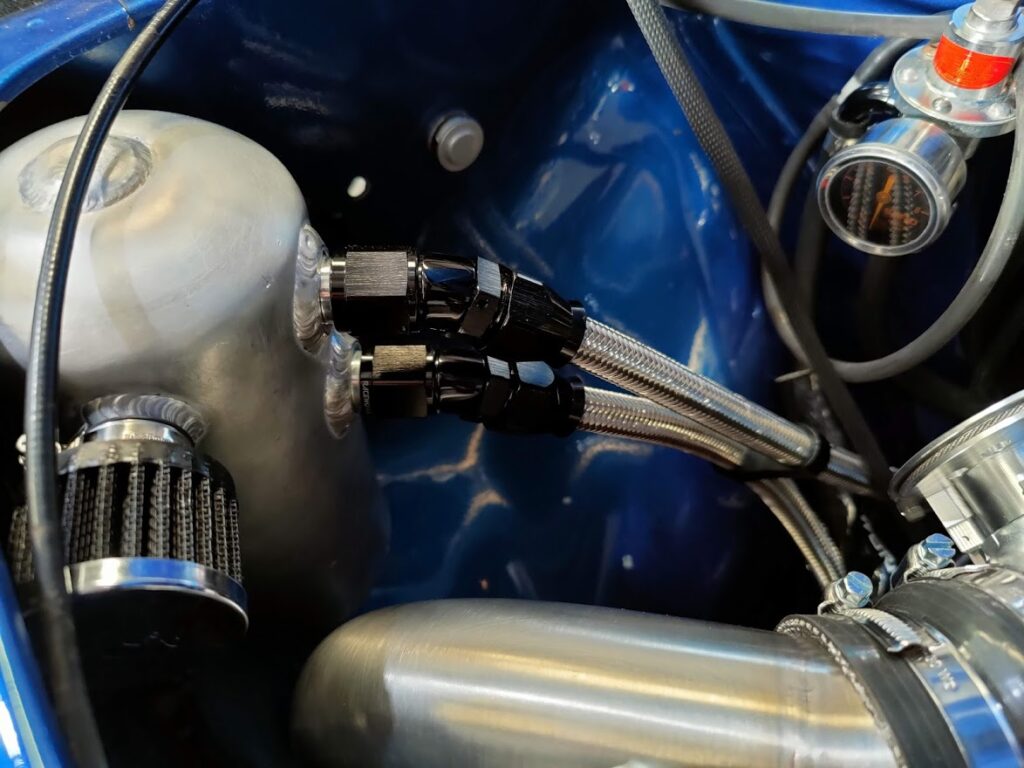

Stainless steel was the material of choice in this instance for the custom 3″ dump pipe and intercooler piping. Heat management was implemented with a Raceworks titanium turbo beanie and titanium wrap to the dump pipe and screamer. All turbocharger oil and coolant lines were assembled with our in-house range of Raceworks aluminium fittings and teflon lined braided hoses.

The old oil catch can was repositioned away from the heat generated by the turbocharger and repurposed with new AN fittings welded to it to allow us to run braided hoses for the crankcase breather lines. We also gave the can and radiator end tank a buff with some scotch-brite to match the intake manifolds ‘raw’ finish. Raceworks knock-in breather fittings were used to allow us to run AN fittings straight off the rocker covers without the need to weld.

Once all of the modifications were in place, we dusted off the Motec cable and after bleeding the cooling system, setting the base fuel pressure and base timing, it was onto the dyno for a retune.

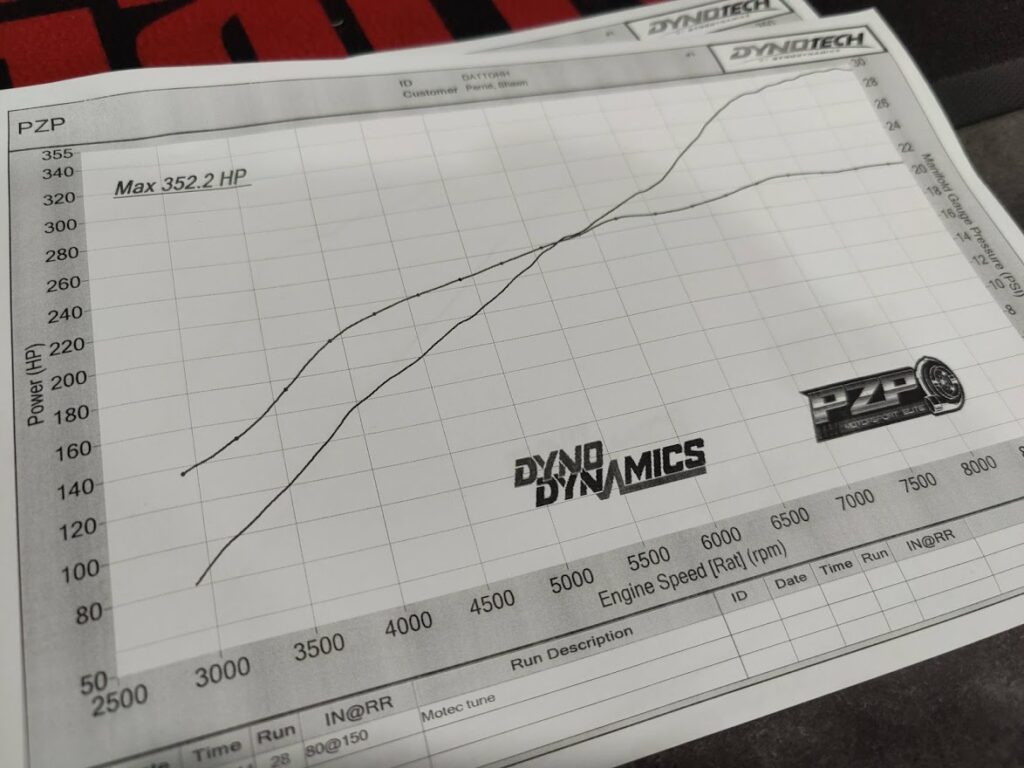

As the fuel system remained untouched apart from the fuel rail, we decided to keep the car on 98 RON fuel. The fuel system was always going to be a bottle neck from the get-go but the injectors were definitely large enough to throw down some boost. Dyno tuning was a great success with the Motec ECU, it had been a while since Tom navigated the old DOS based software but after a few hours on the rollers we reached our injector duty cycle limit at around 20psi of boost.

A healthy 350 rear wheel horsepower was the result; pretty impressive for a 1.8L small cam, auto trans with only a bit of boost! So what does 350rwhp feel like in a 700kg vehicle….. wow! A number in the 400’s would have been nice to finish off but “Rome wasn’t built in a day” and the huffer has plenty more in it when the time comes to do a few more upgrades. Stay tuned for a 1/4 mile timeslip coming soon!

Check out the dyno here and please do us a favour by liking and subscribing to our YouTube channel.